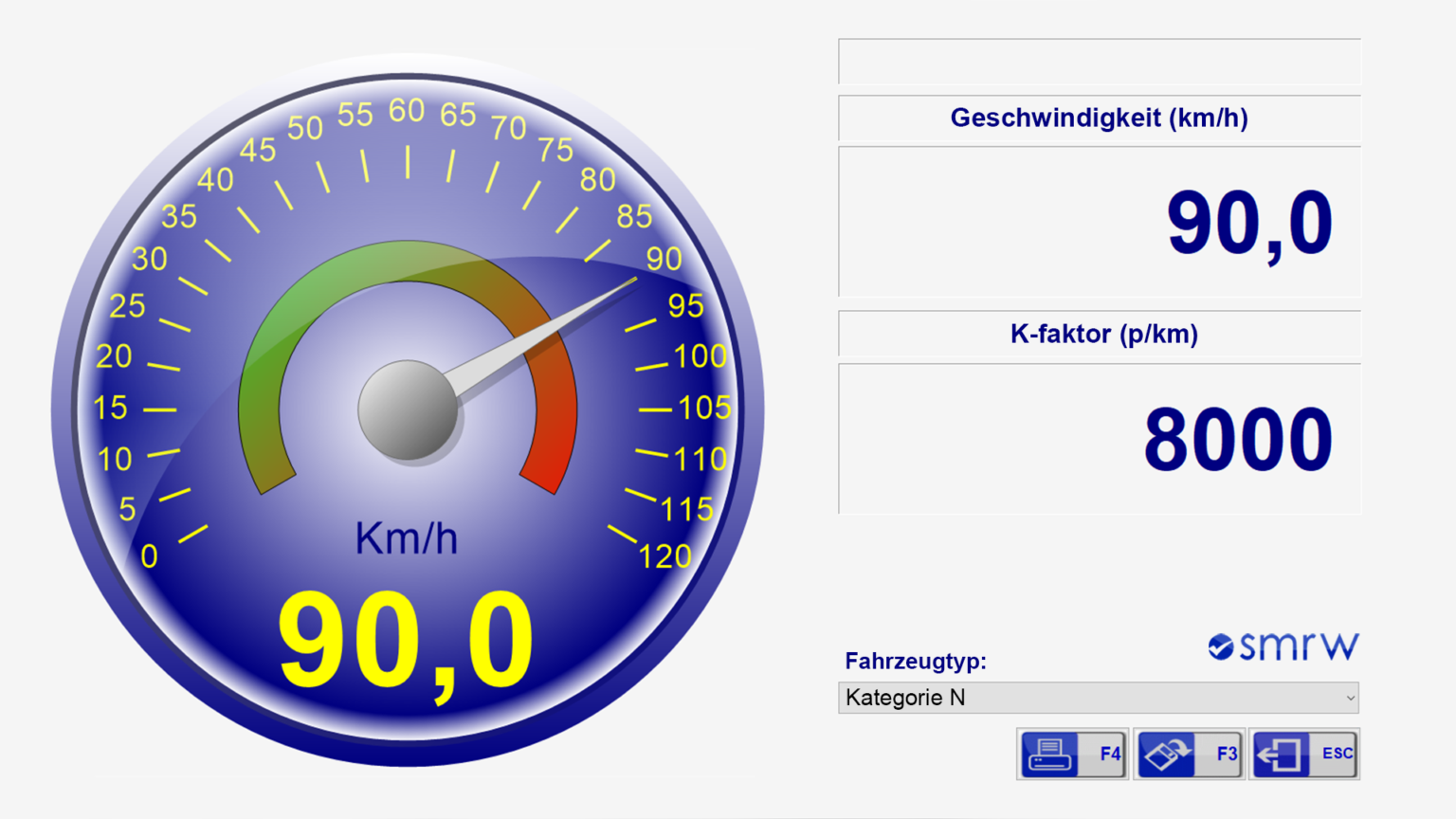

Speedometer VTU-N

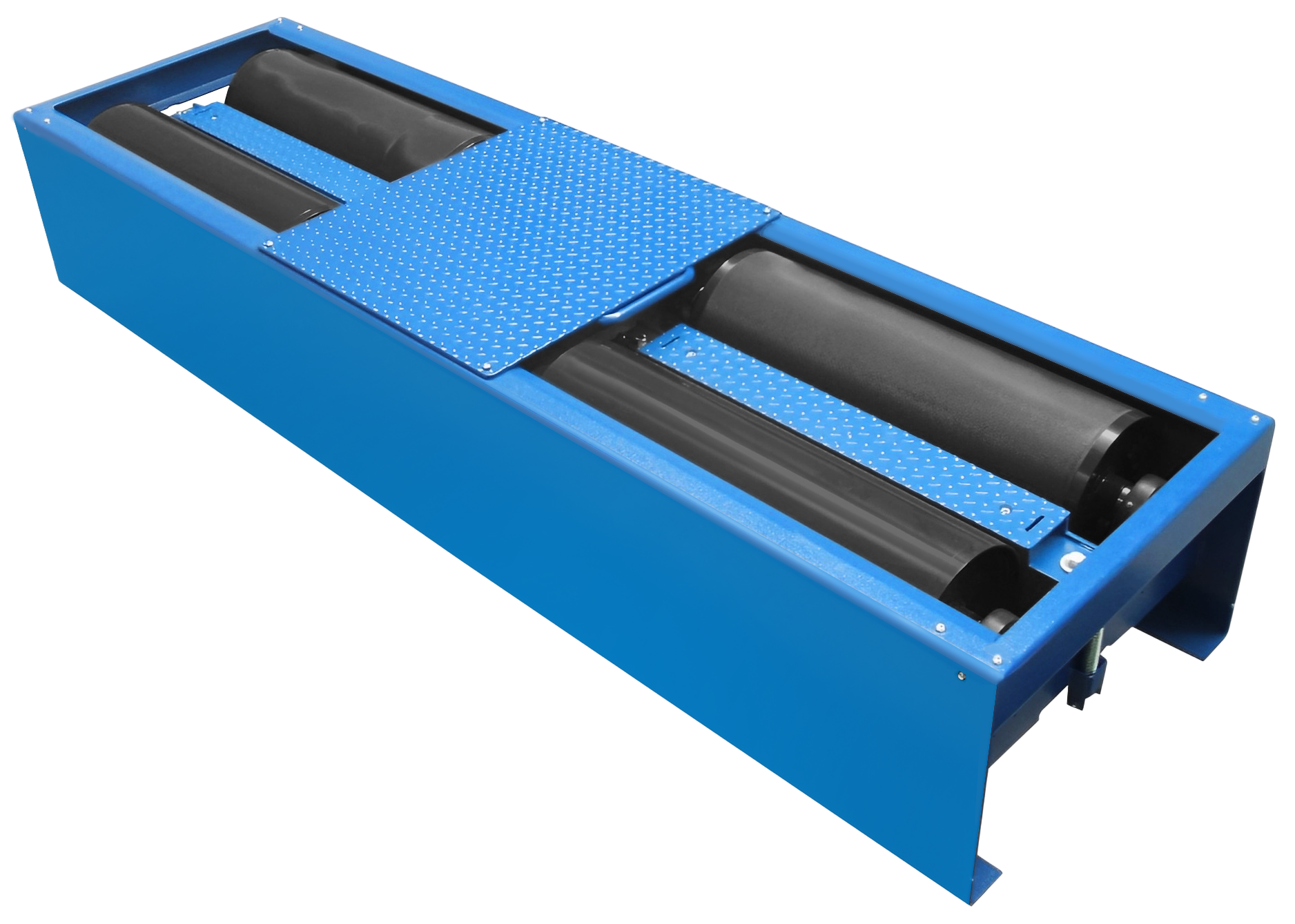

The Speedometer VTU N is designed to verify the status of the odometer, speedometer and tachograph for vehicles up to 16 T. Updating of tariffs with password validation.

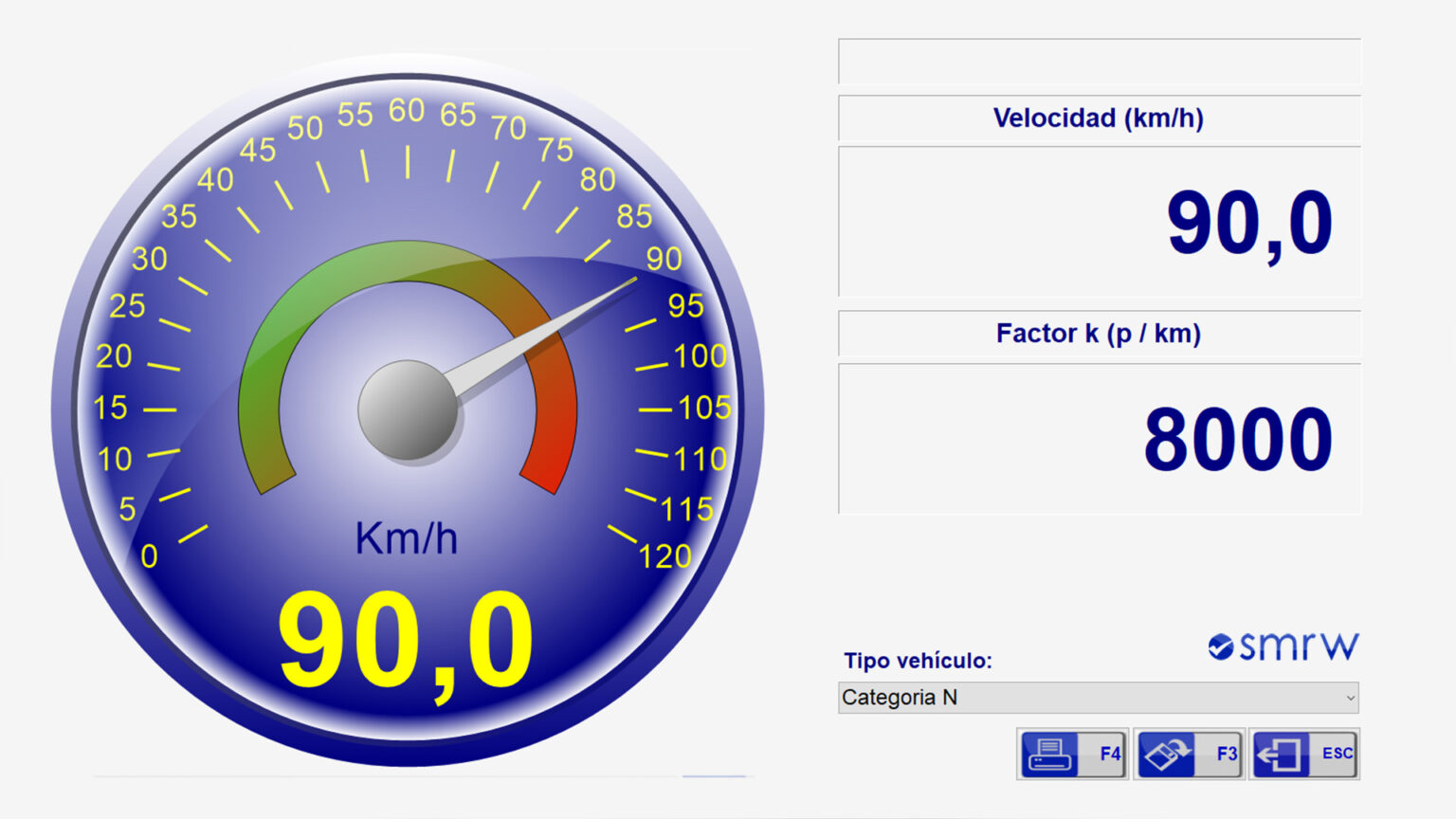

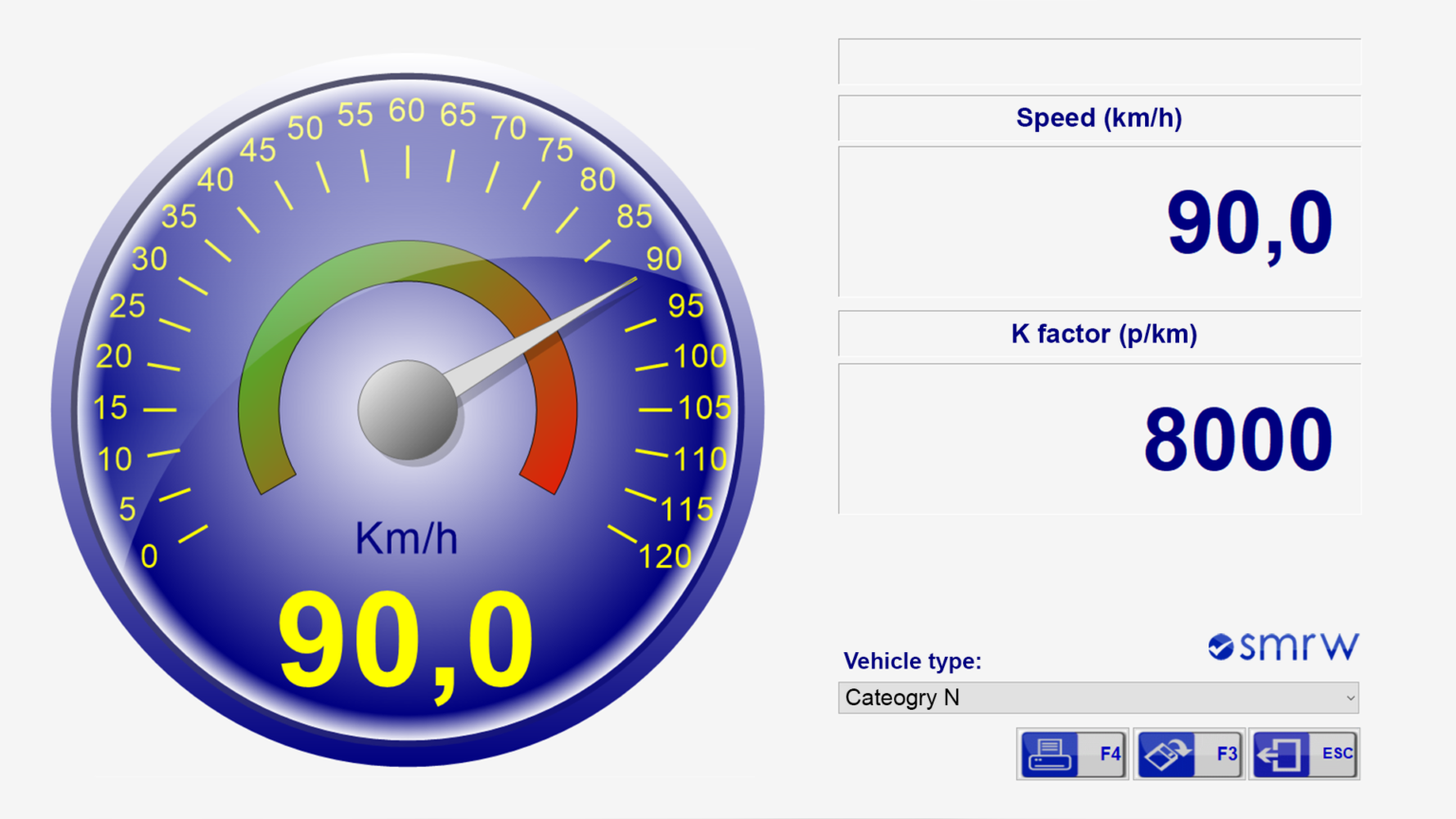

The speedometer compares the speed indicated by the technician and the actual speed, finding the difference between the two in %. The tachograph test shall record both the distance indicated by the technician and the actual distance travelled by the vehicle, also finding the difference between the two in %.

The taximeter test identifies the charging error, according to the tariffs in force, marking in red if the value is outside the parameters.

The measurement system is based on a high-resolution encoder and incorporates a photocell to calculate the error introduced by tyre deformation.

The speed measurement is obtained by means of an impulse sensor mounted on one of the rollers.

The surface of the rollers is smooth and coated with an anti-rust treatment, which gives the rollers a long service life.

The speed measurement is obtained through an incremental encoder mounted on the front roller shaft.

Rear roller that can be adjusted to fit different wheel diameters.

Standard equipment

- Universal speedometer

- Control console

- Roller covers

- Electronic control and SMRW Software

- Pneumatic lift for easy exit

- Safety stops to prevent sideways exit

- Special rollers for superior adhesion

Odometer/Speedometer tests

- Checking and evaluation of results on different routes

- Testing and evaluation of results at different speeds

Console for implantation speedometer equipment

Technical data

- Maximum axle load16 T

- Maximum test speed120 km/h

- Min. / max. track width805 - 2,635 mm

- Measuring step1 km/h / 0.1 m

- Roller locking systemPneumatic

- Voltage230 V 50 Hz

- Length of rollers900 mm

- Outside diameter of rollers318 mm

- Distance between roller axles456 mm

-

Pneumatic supply

6 bar (recommended)

Software

Ryme Worldwide has SMRW (Software Maquinaria Ryme Worldwide) for its equipment, which is responsible for collecting information from our equipment and peripherals, analysing it and displaying it on the information output device. All of this is accompanied by the necessary electronics to optimise performance to the maximum.

Work in your inspection centre or workshop in the fastest and most efficient way with the operation of our Ryme Worldwide Machinery Software.

A unique way of working designed to make the inspector's job easier.

No redundancies, what you need, when you need it, how you need it. Read more

Get to know all our software and management systems