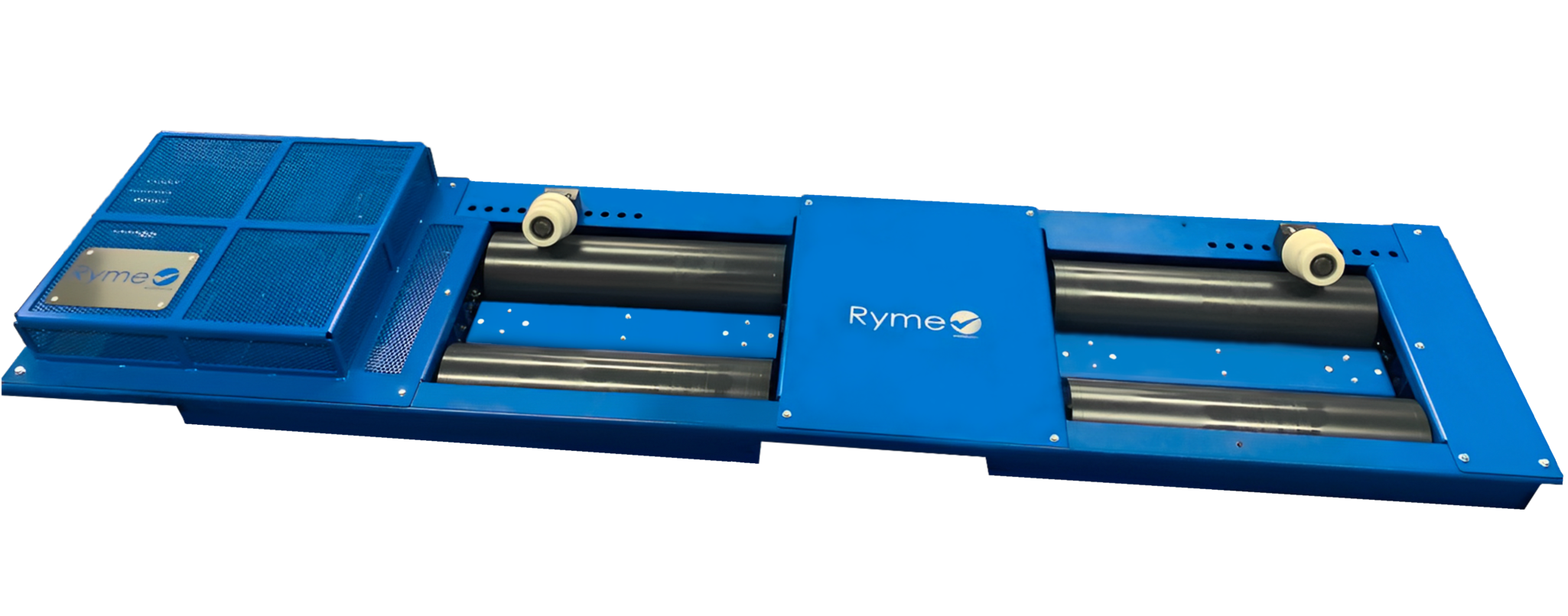

Banco de emisiones por simulación de aceleración ASM 2WD

El banco de emisiones ASM para vehículos de tracción 2WD puede prevenir, localizar e investigar posibles problemas de encendido e inyección, así como mejorar el consumo de combustible y medición de las emisiones de gases del vehículo bajo carga.

Durante los ensayos de emisiones, se produce una absorción de la potencia acorde con el estándar ASM mediante un freno eléctrico autorefrigerado por aire. Está formado por un bastidor monocasco de acero que alberga cuatro rodillos de 350 mm. Los rodillos delanteros están recubiertos de carburo de tungsteno para mejorar la adherencia del vehículo y evitar el desgaste de los rodillos.

Incluye un freno eléctrico de alta absorción energética. Además, para facilitar el acceso y salida del vehículo, dispone de un mecanismo elevador bloqueador accionado neumáticamente.

Compatible con nuestros analizadores de gases EIS-5000, RY-500AG y RY-4000AG (Click en los nombres para conocer cada analizador)

Equipamiento estándar

- Banco dinamométrico 2WD

- Consola de control

- Control electrónico y software SMRW

- Mando a distancia para control de la prueba

- Módulo analizador de hasta 5 gases

- Sonda de muestreo

- Estación meteorológica

- Simulación de cargas mediante el freno Foucault

- Sistema de elevación central con bloqueo automático de rodillos para facilitar la salida del vehículo

Datos técnicos

Datos técnicos banco dinamométrico

- Carga máxima por eje4 T

- Velocidad máxima de prueba70 km/h

- Ancho de vía mín. / máx.760 - 2.480 mm

- Escalón de medida0,1 km/h / 0,1 HP

- Sistema de bloqueo de rodillosNeumático

- Voltaje400 V 50 Hz

- Longitud de los rodillos860 mm

- Diámetro exterior de los rodillos218 mm

- Distancia entre ejes de rodillos440 mm

- Alimentación neumática8 Bar mín.

- ConexionesRS 232

-

Resolución de medida

± 0,1 km/h

Datos técnicos analizadores de gases

- Analizador de gases RY-500AG

- Analizador de gases EIS-5000

- Analizador de gases RY-4000AG

Software banco dinamométrico + analizador de gases (muy pronto)

Ryme Worldwide dispone para sus equipos el SMRW (Software Maquinaria Ryme Worldwide), el encargado de recoger la información de nuestro equipamiento y periféricos, analizarla y mostrarla en el dispositivo de salida de información. Todo ello, acompañado de la electrónica necesaria para optimizar el rendimiento al máximo.

Trabaja en tu centro de inspección o taller de la forma más rápida y eficiente con la operativa de nuestro Software de Maquinaria Ryme Worldwide.

Una forma de trabajar única y pensada para facilitar la tarea del inspector.

Sin redundancias, lo que necesitas, cuando lo necesitas, como lo necesitas. Saber más

Conoce todos nuestros software y sistemas de gestión

Multilenguaje 🌎