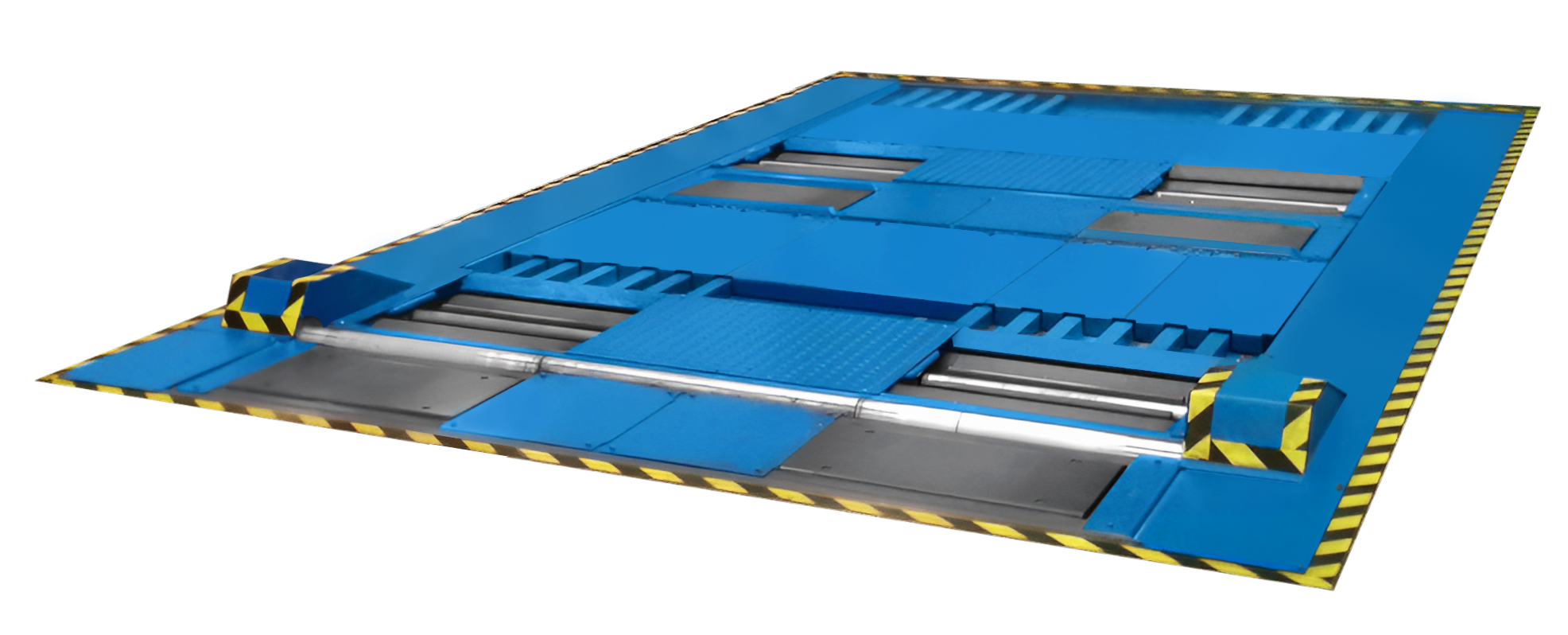

Tandem inspection line

The Tandem inspection line consists of a side slip tester and two pairs of brake and suspension test frames, one of which is fixed and the other movable to automatically adjust to the specific wheelbase of the vehicle.

The positioning is very precise thanks to a transducer that constantly sends the position of the mobile frame to the machine's control and management electronics.

With this revolutionary inspection line and proper vehicle flow management it is possible to reduce test time by more than 50%, and consequently increase the productivity of the inspection line by more than 100%.

Standard equipment

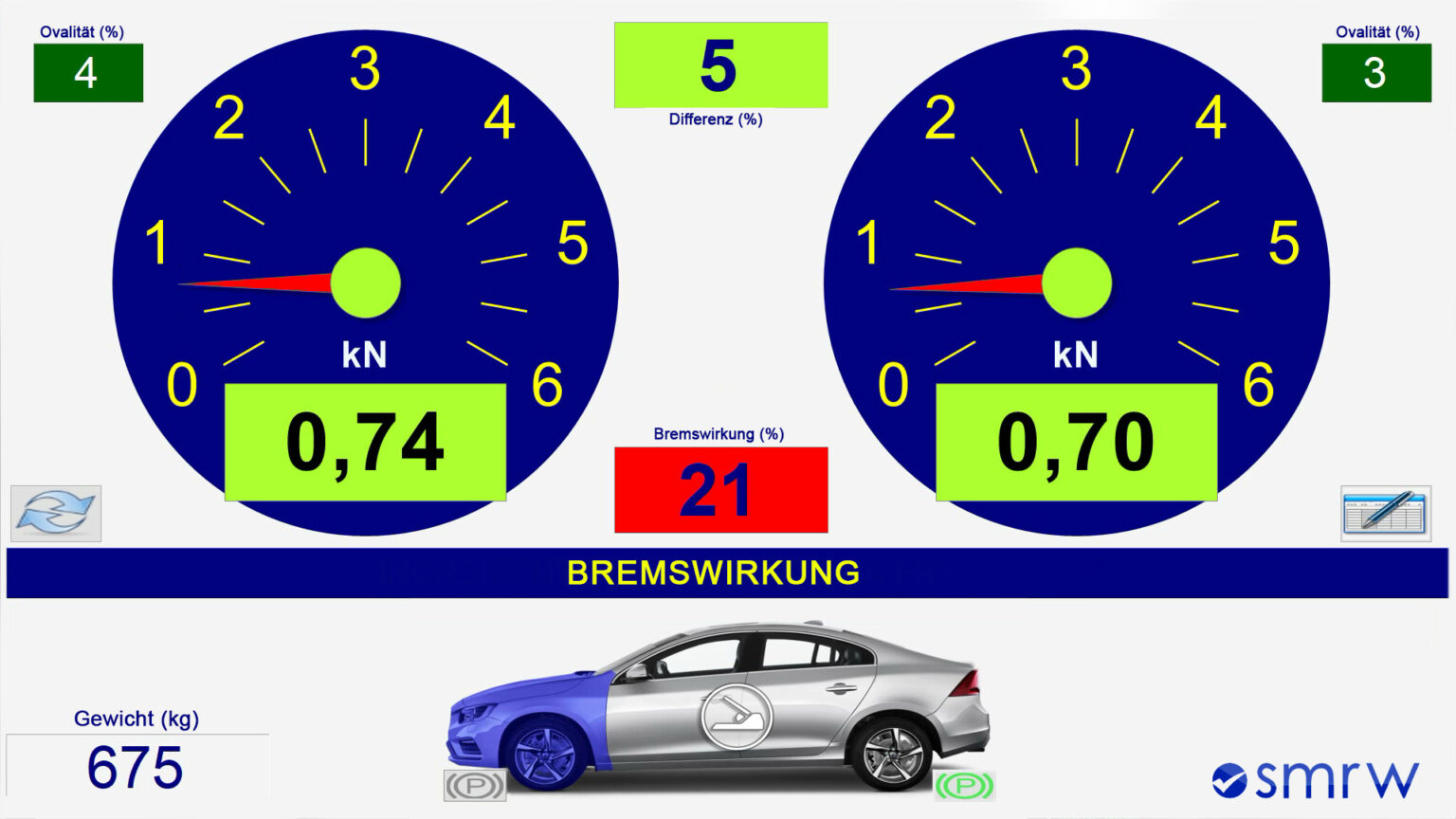

- Brake tester

- Suspension bench

- Side slip tester

- Control console

- Self-locking rollers for easy exit

- Electronic control and SMRW Software

Console for light vehicle equipment

Technical data

Main features

- Maximum axle load3,5 T

- Min. / max. track width880 - 2,174 mm

- Voltage400 V 50 Hz

- Fuse protection3 x 50 A

- Thermal protector4 x 9 - 12'5 A

- Min. / max. wheelbase2,300 - 3,060 mm

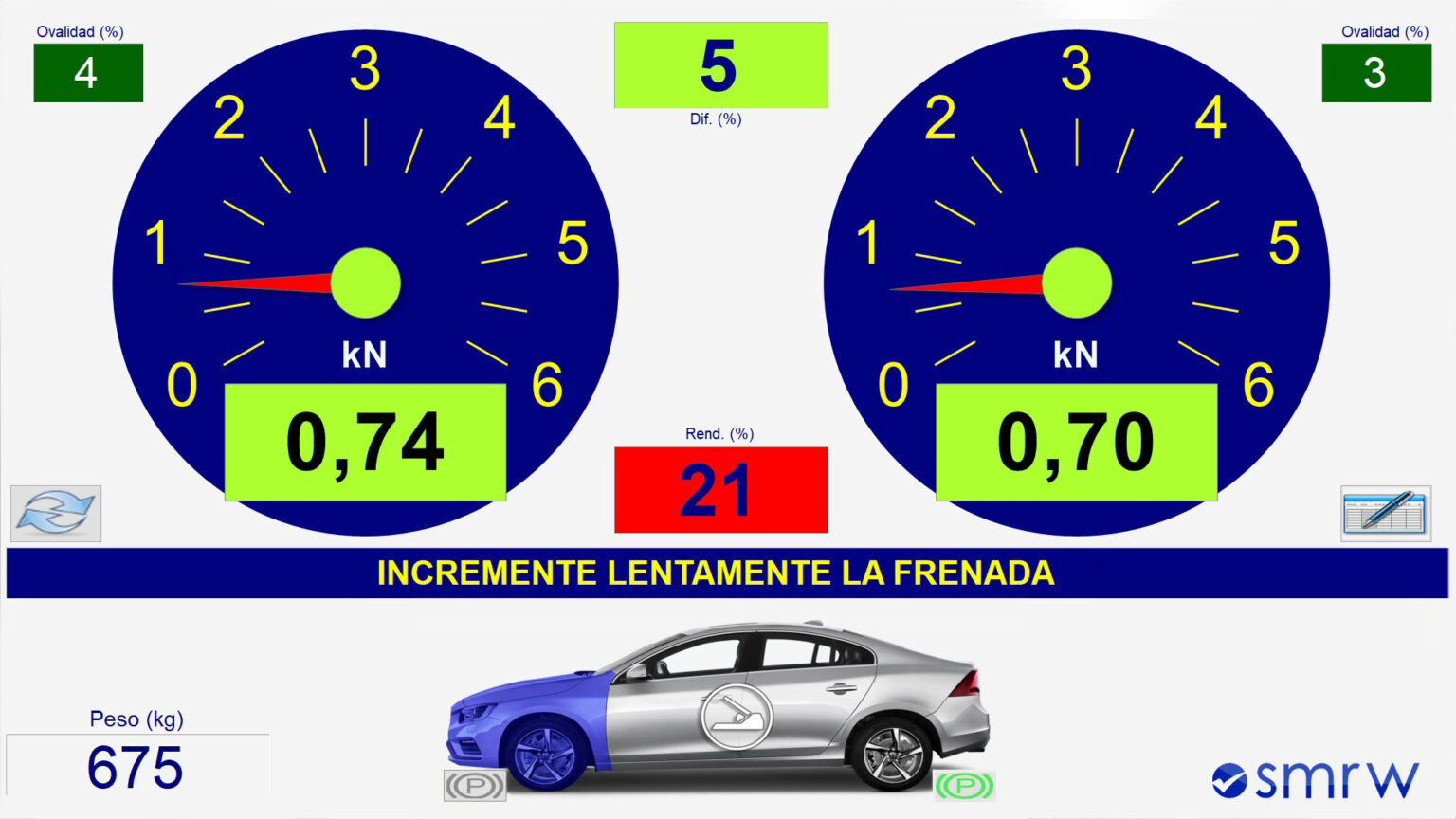

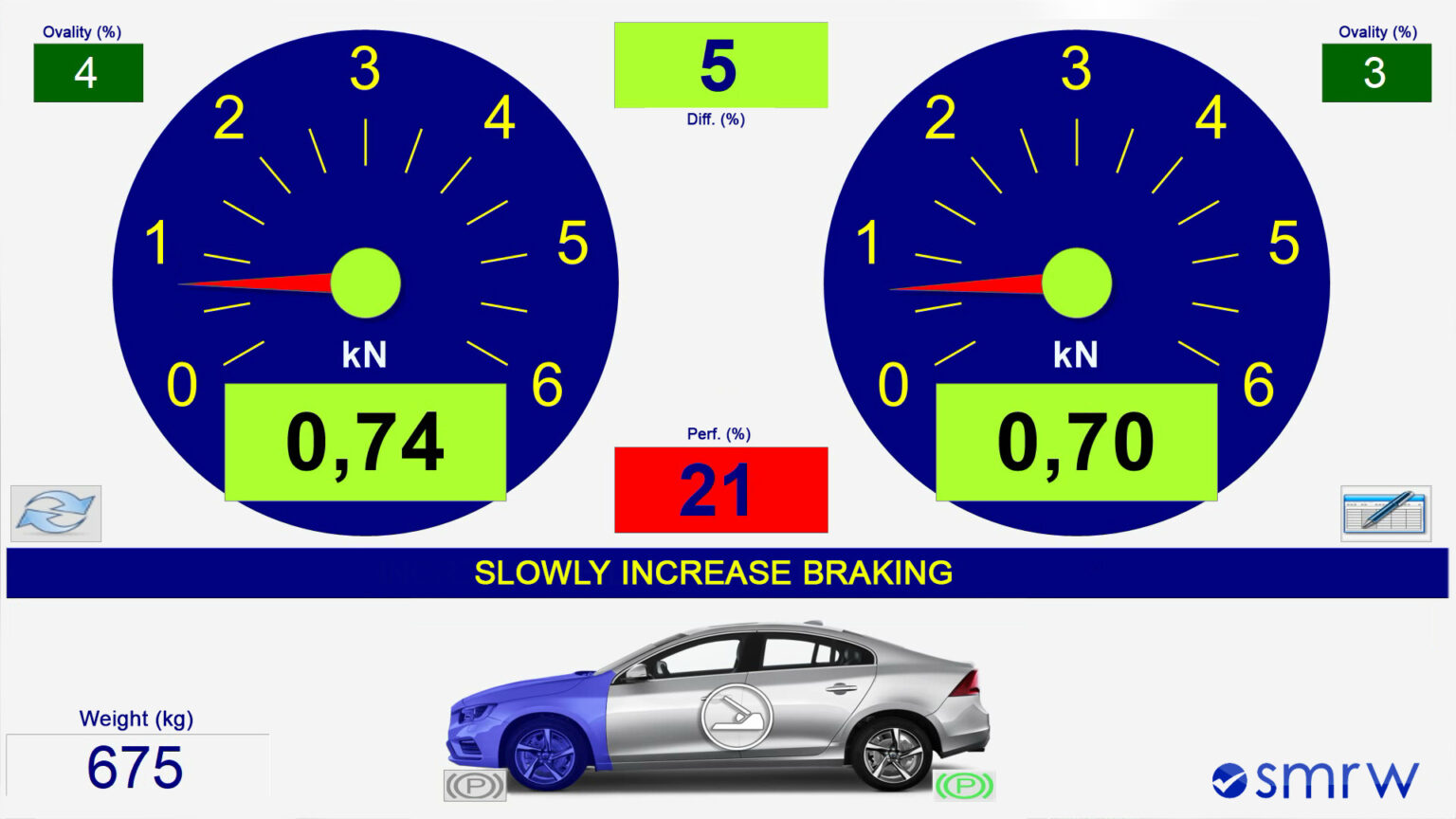

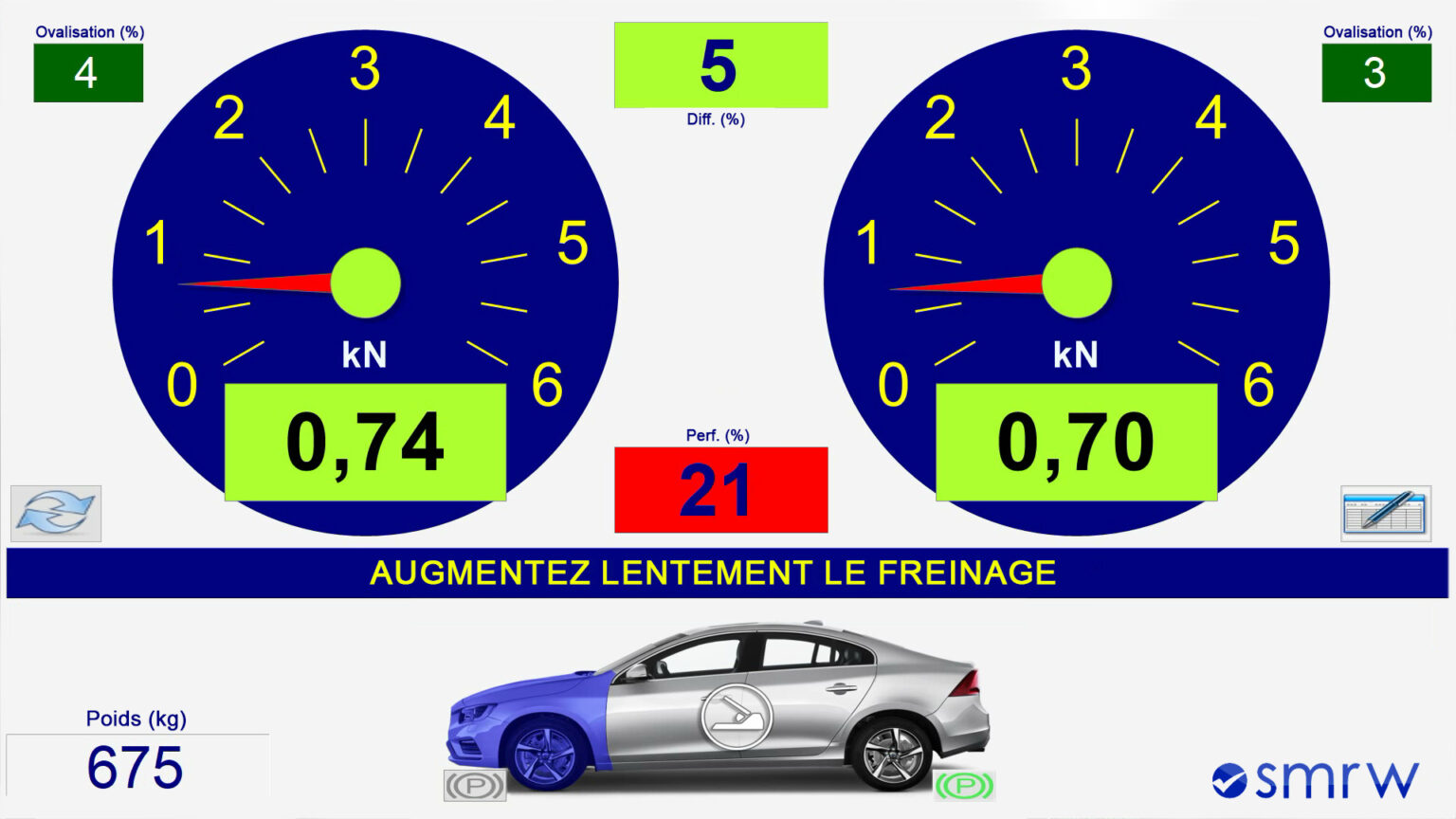

Brake tester

-

Roller diameter

Front: 155 mm, Rear: 208 mm

- Test speed3.5 km/h

- Engine power4.6 kW

- Length of rollers (front, rear)684 mm

- Useful length of the rollers647 mm

- Distance between centres400 mm

- Adhesion coefficient0,9 dry - 0,7 wet

- Measurement scale0 - 6 kN

- Measuring step0'01 kN

- Measurement error indication1%

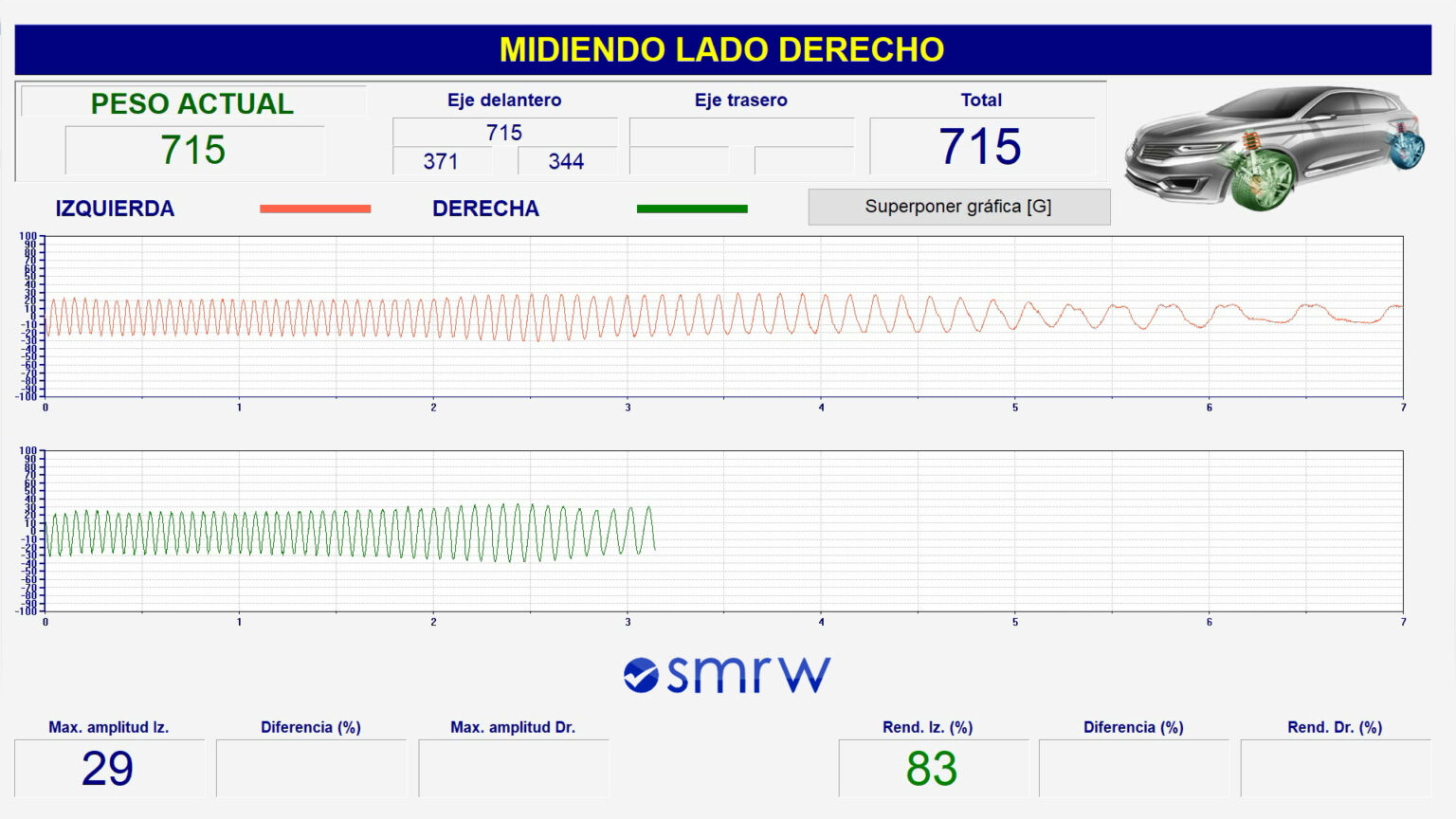

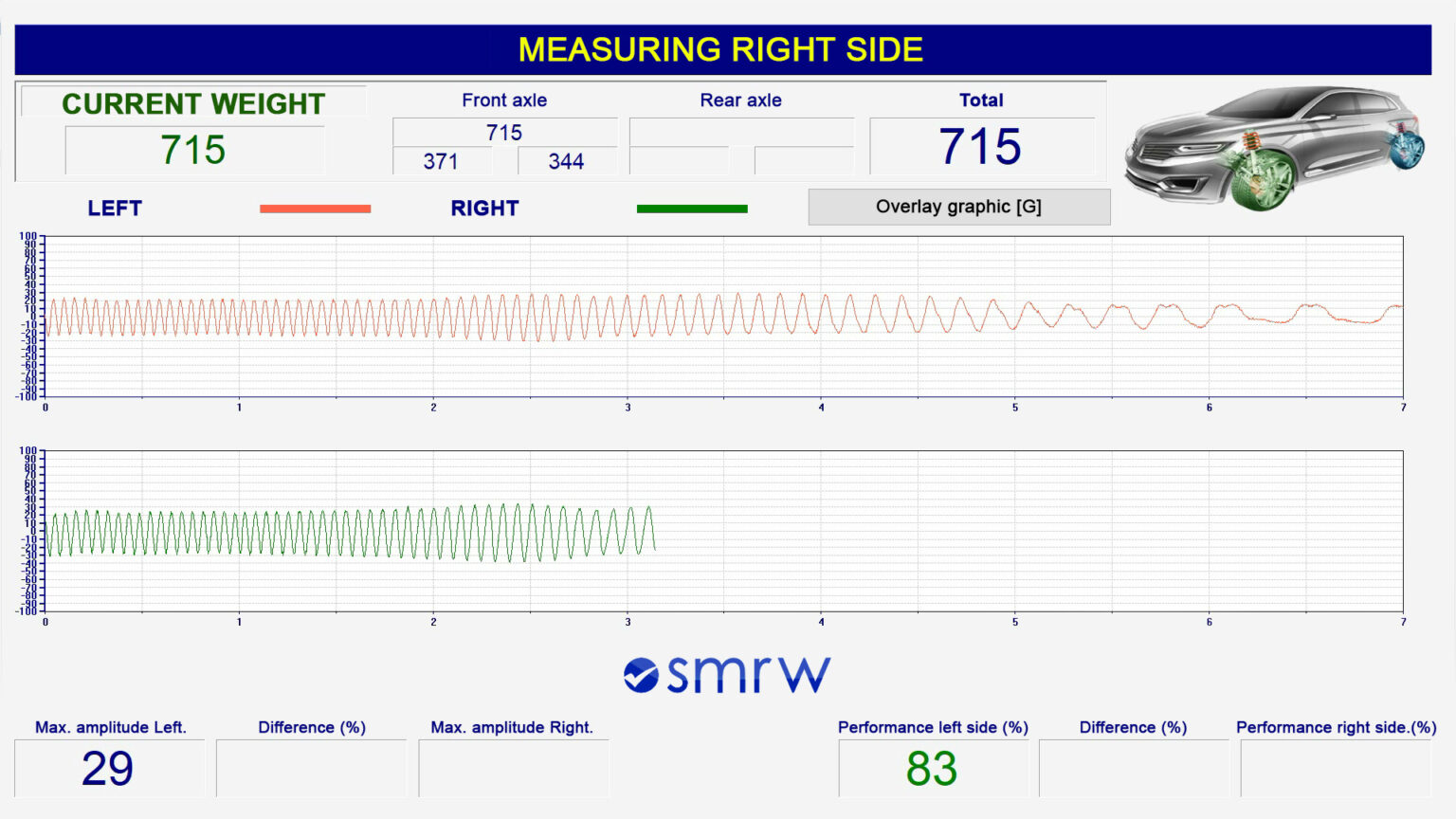

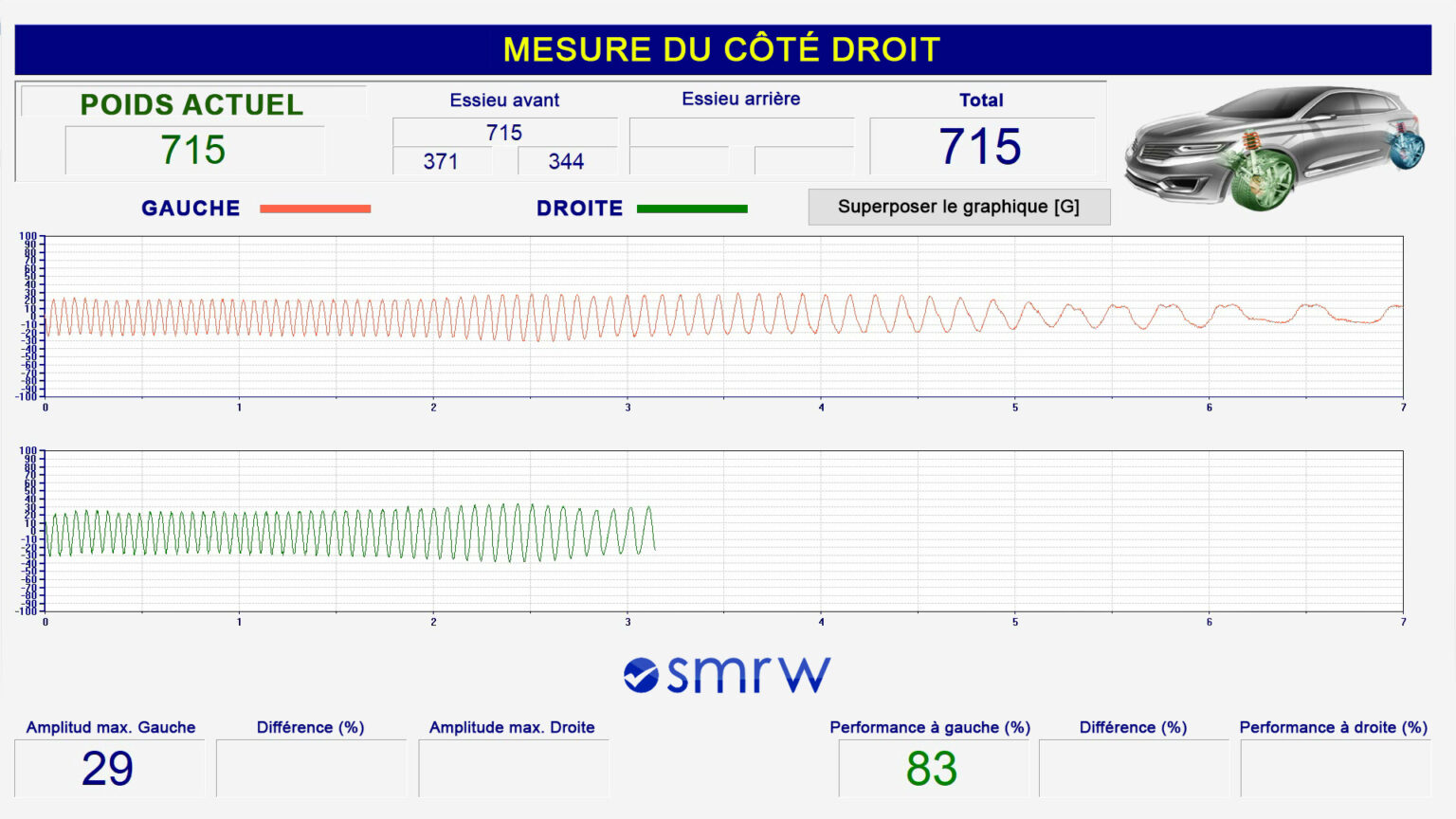

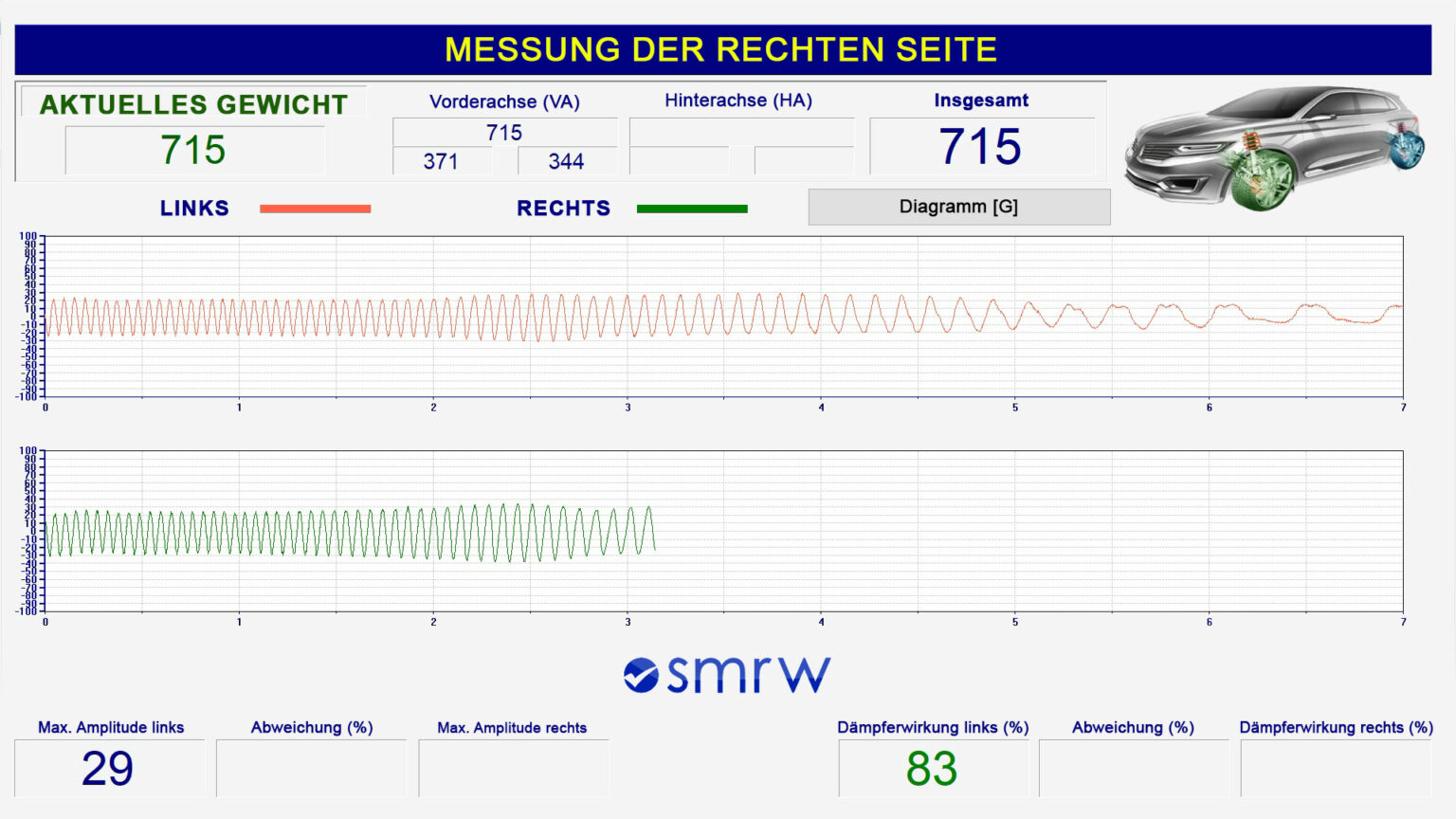

Suspension bench

- Engine power3 kW

- Excitation frequency16 Hz

-

3 levels of measurement

A. Amplitude

B. Performance

C. Graphics

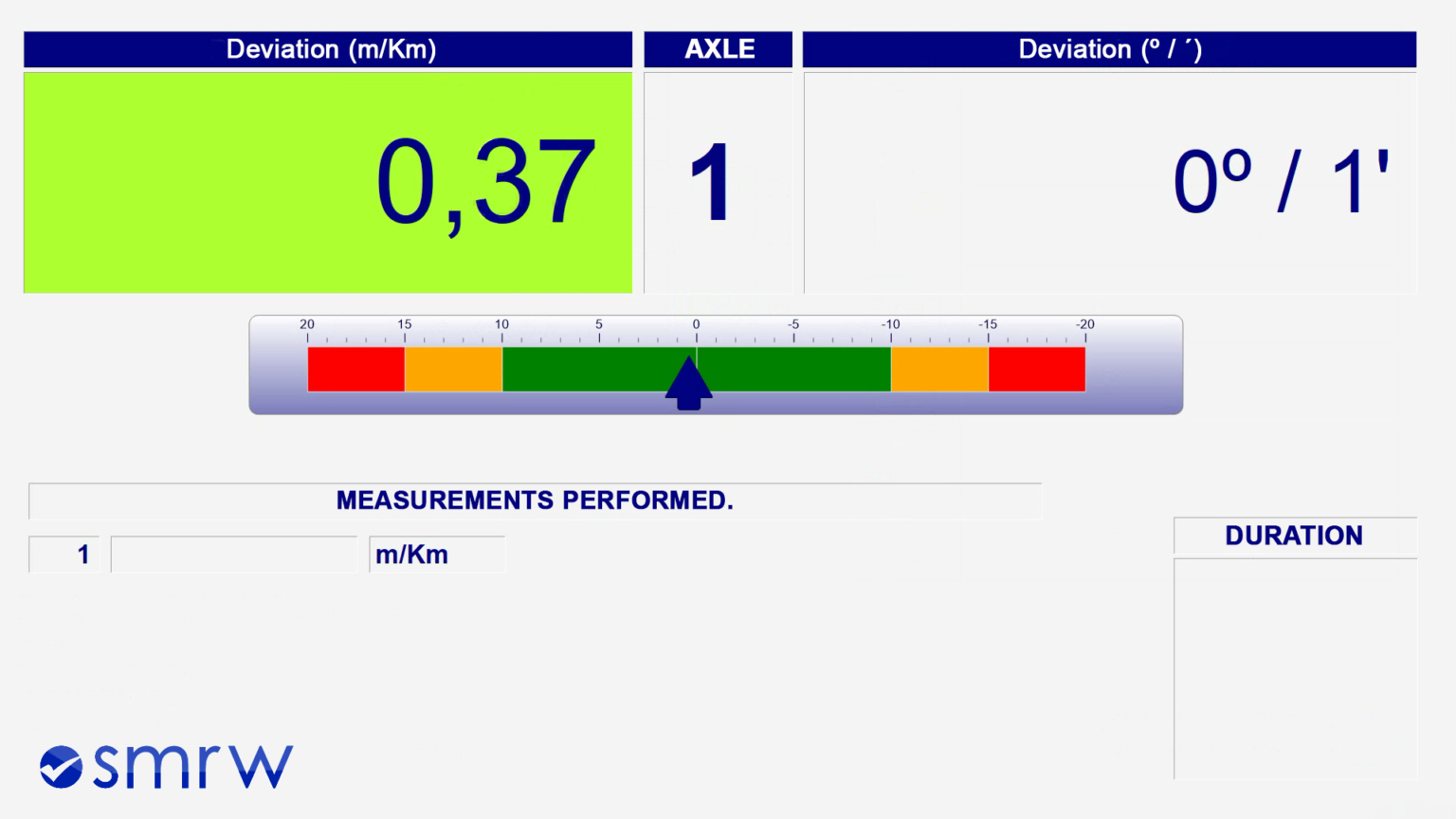

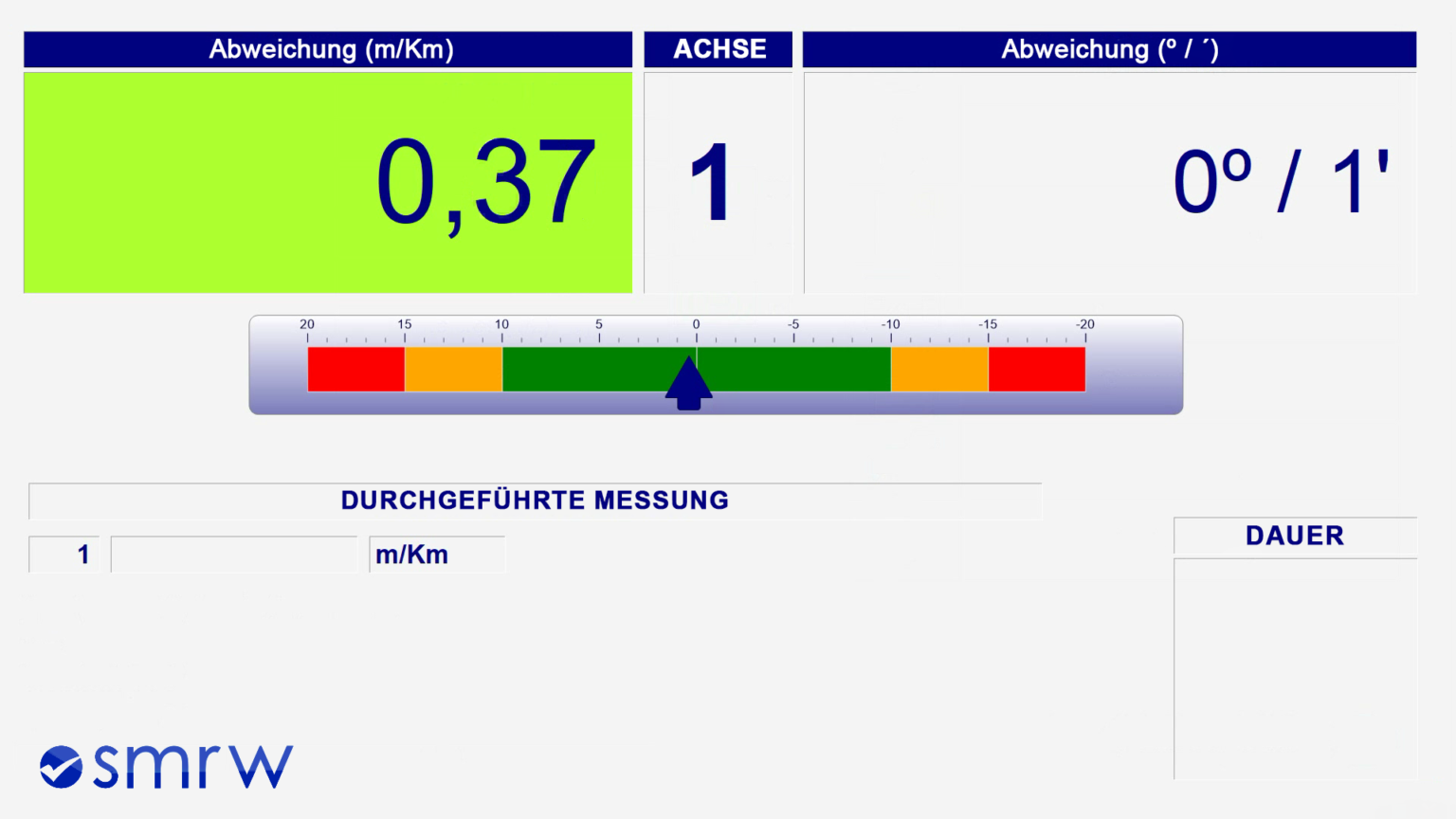

Side slip tester

- Pace speed5 - 10 km/h

- Measuring range0.1 m/m / 0.1 m/km

- Measuring step-20 - 20 mm/m

-

3 levels of measurement

A. m/km

B. Degrees and minutes

C. Graphic/Bar

Software Aligner + Suspension Bench + Brake Tester

Ryme Worldwide has SMRW (Software Maquinaria Ryme Worldwide) for its equipment, which is responsible for collecting information from our equipment and peripherals, analysing it and displaying it on the information output device. All of this is accompanied by the necessary electronics to optimise performance to the maximum.

Work in your inspection centre or workshop in the fastest and most efficient way with the operation of our Ryme Worldwide Machinery Software.

A unique way of working designed to make the inspector's job easier.

No redundancies, what you need, when you need it, how you need it. Read more

Get to know all our software and management systems

Powered by Worldwide Group © technology